Custom Casting/ Machining Parts for Valve/ Pump/ Gearbox Body/ Shell/ Housing/ Casing/ Turbocharger Parts

Basic Info.

| General Products Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

| Main blank Process for Steel Casting | Investment casting (wax mold made by middle temperature wax) /Precision casting ; Lost Wax Casting (wax mold made by low temperature wax)/ Precision casting; |

| Blanks Tolerance -Casting Tolerance | CT7-8 for Lost wax Casting Process CT4-6 for Investment casting Process |

| Applicable Material | Stainless Steel: CF8, CF8M, . G-X6CrNiMo1810, G-X7CrNiNb1189, SUS 304, 304L, 316, 316L. OR According to customer requirement Carbon steel, Low Carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, Copper alloy Brass: HPb59-1, CuZn39Pb1/2/3, CuZn40, C36000, C37710, C67400, etc. Aluminum Bronze: QAl11-6-6, CuAl10Fe2/3, CuAl10Ni5Fe5, C65500, C95600, C87500 Sn Bronze: CuPb5Sn5Zn5, C83600, C84400, C86500. etc. |

| Casting Blank Size /Dimensions | 2 mm-600mm / 0.08inch-24inch according to customer requirement |

| Casting Blank Weight | Range from 0.01kg-85kg |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

| Applicable Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

| MOQ | For casting: 200pcs For machining: 500pcs |

| Lead Time | 30-45 days for mass production |

Product Description

Item: Turbocharger for Tuning

Casting process: receiving drawings or samples---- quotation---trial mold production---mold making---mold design---sample confirmation---batch production---mass production.

Technological process:

According to the customer's drawings,automatic balancing machine tools, castings with high technical requirements.

Customization of aluminum alloy die castings: Die Casting Aluminum customization of auto parts, die opening customization of aluminum parts of pump housing, die casting of aluminum alloy valve cover, aluminum alloy valve cover, radiator back cover, die casting and die opening of motor aluminum housing, electronic housing accessories castings.

| Country of Origin | China | ||

| Port of Loading at Origin | Qingdao | ||

| Product Specifications | Aluminium with no. A102 for Compressor Housing | ||

| Steel with no. HT250 for bearing housing | |||

| High SI MO Ductile iron for turbing housing | |||

| Working Temp. 700 center degree to 750 center degree | |||

| Working Top limitary Temp. 950 center degree | |||

Casting parameter

| Item | Machinery casting |

| Service | Process according to customer drawings |

| Process Technology | Gravity casting, shell mold casting, pressure casting Strong design team and computer ability, software: Autocad, Solidworks. Roughness tester, hardness tester, salt spray tester |

| Size | Customized as customer's drawings |

| MOQ | Customized |

| Processing | 1, Sign Drawing (General clients provide the drawing or samples) 2, Opening the Mold 3, Die Casting 4, Precision Machining 5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing 6, Inspection and Packing |

Please Attention

The picture and prices shown here are just for exhibition and display. The products in the picture are all private molds. If you need to place an order for production, please provide drawings or samples for mold opening production.

Our advantage

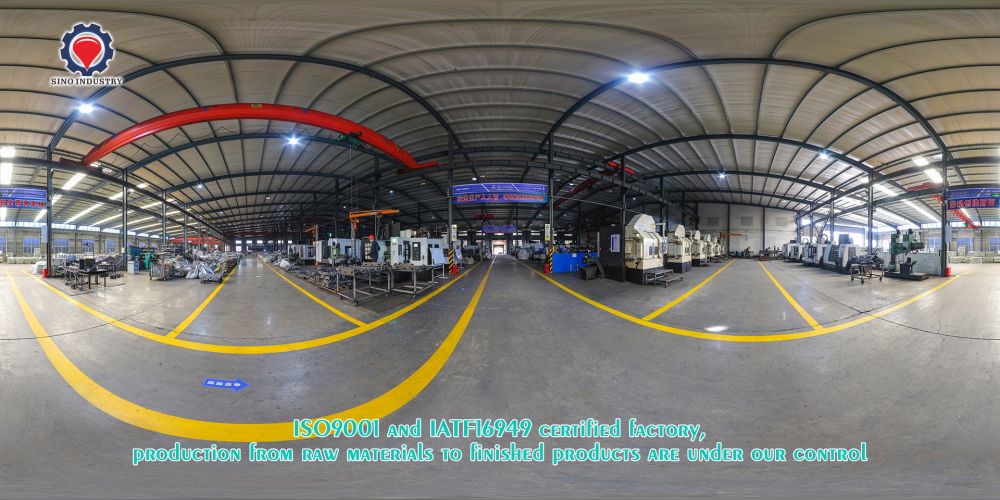

1.Our company has professional engineering R&D department, mold department, stamping department, polishing department, quality inspection department, packaging department, sales department, after-sales department, and logistics department.

2.Our company has advanced and perfect precision casting supporting equipments, German spectrum analyzer and test equipment, metallographic microscope, 1200kN press and mechanical performance test equipment, multi-element analyzer, Richter hardness tester, helium pressure leak detector and other test equipments.

3.We can design molds and produce casting products according to customers' requirements, samples and drawings, and make all kinds of rough parts and finished parts.

4.we have matching production equipments, including rapid high-frequency melting furnace, resistance melting furnace, horizontal pouring machine, turnover pouring machine, low-pressure casting machine, quenching furnace, curing furnace, shot blasting machine, sand blasting machine, laser cutting machine, laser welding machine, ion cutting machine, CNC machining center, milling machine and other equipments.

Quality Control

1) Checking the raw material after they reach our factory --- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production --- In process quality control(IPQC)

4) Checking the goods after they are finished --- Final quality control(FQC)

5) Checking the goods after they are finished --- Outgoing quality control(OQC)